LONGINES Precision

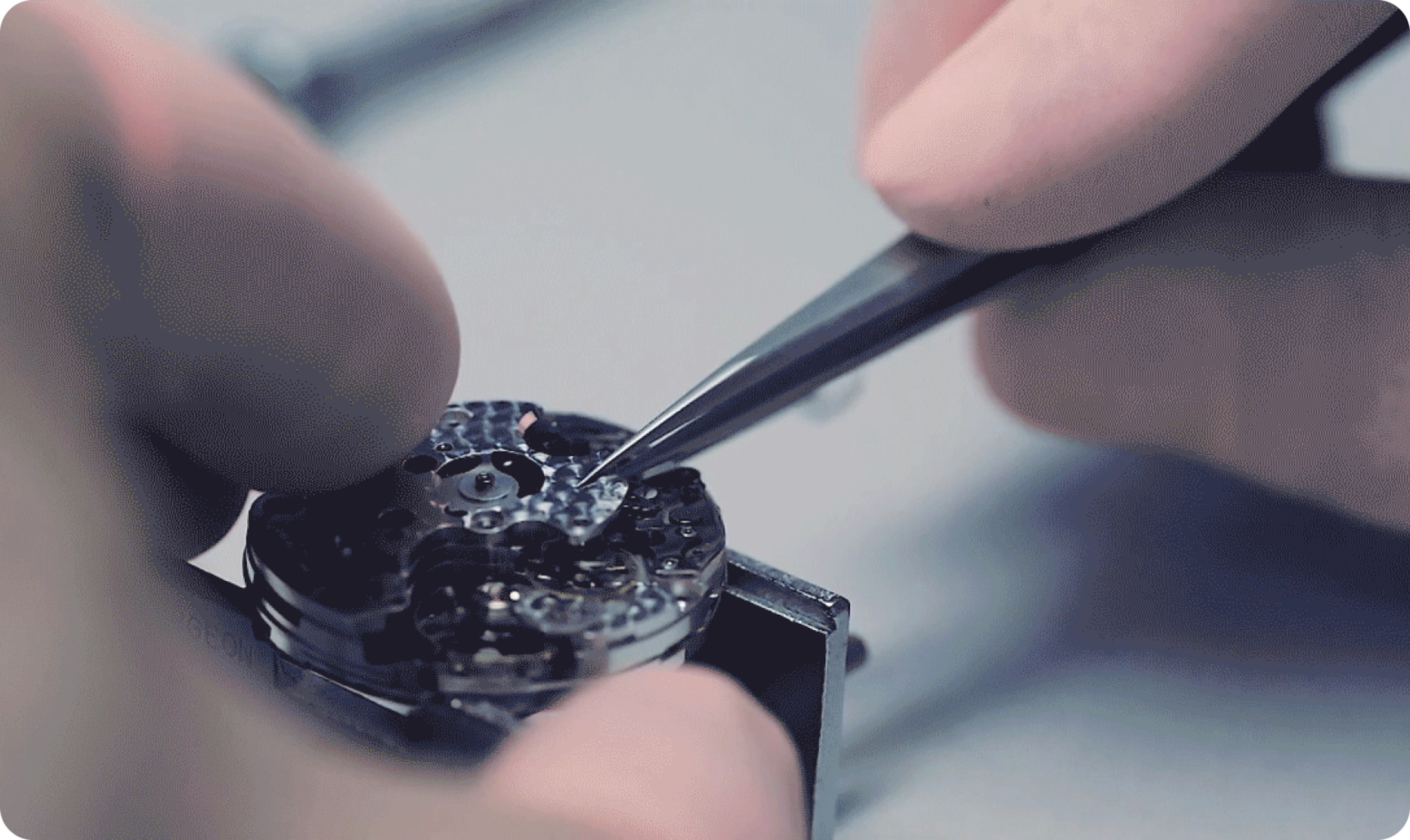

Your timepiece reflects an expertise steeped in Tradition, Elegance and Performance. Endowed with a high technical know-how and expertise, our expert watchmakers work all over the world.

From the most recent to the oldest pieces, from the simplest to the most complicated movements, from steel to jewelled watches, we take care of the timepieces entrusted to us with skill and care.

Our know-how in video

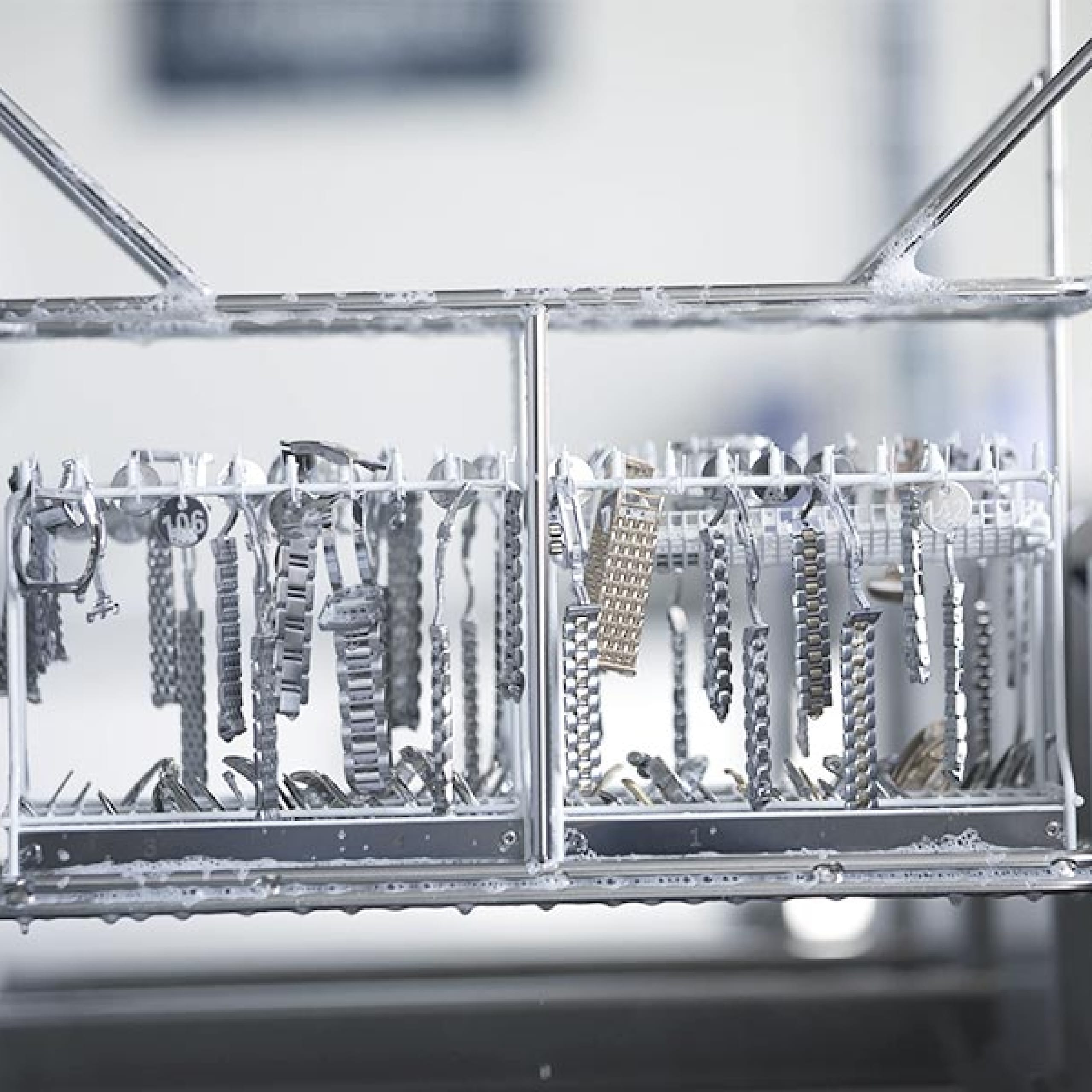

FULL SERVICE

The audio description stays synchronised with the video.

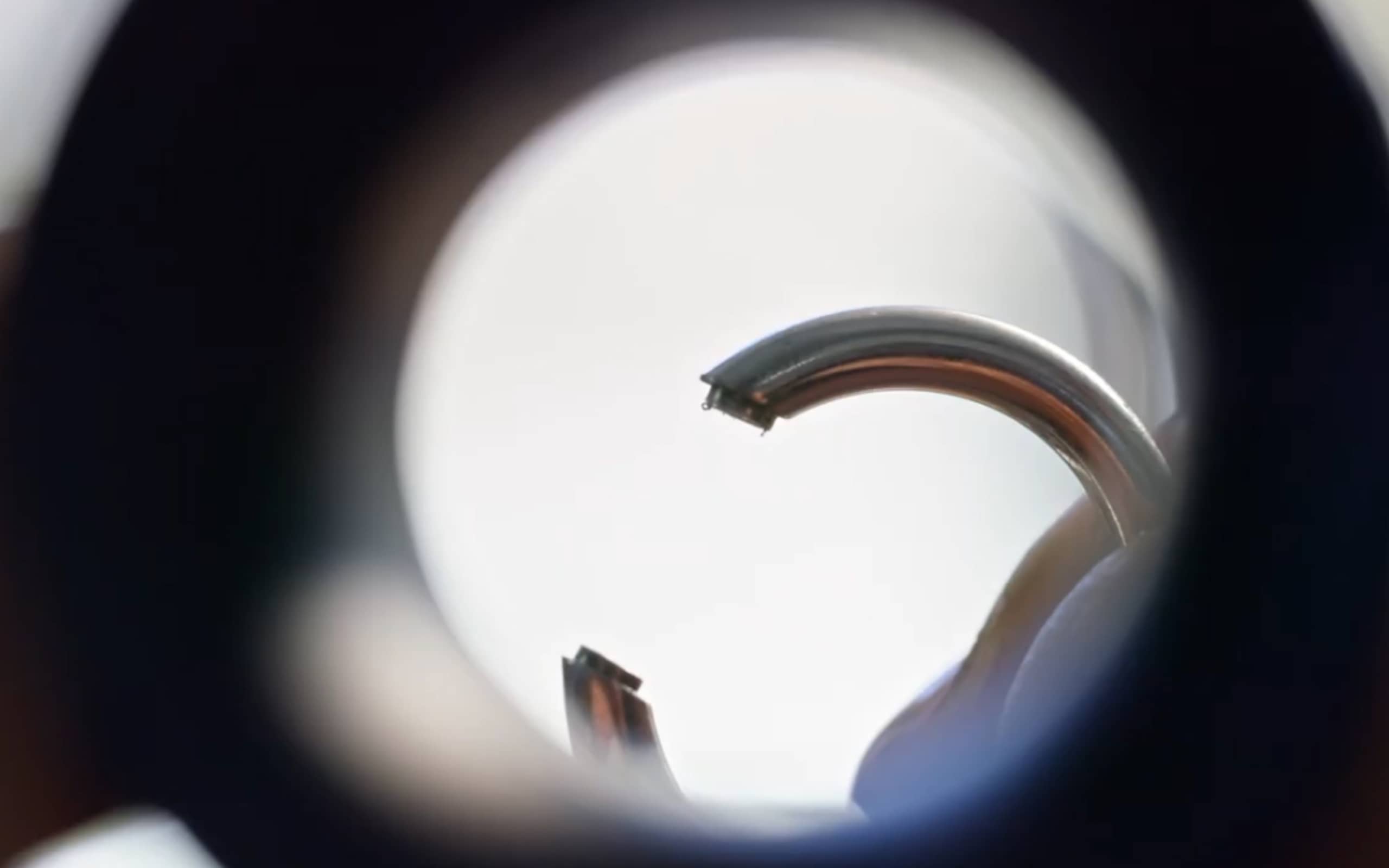

Transcript : A full service restores the function and aesthetic aspect of your watch. It includes a disassembly and a replacement of worn components inside the movement.

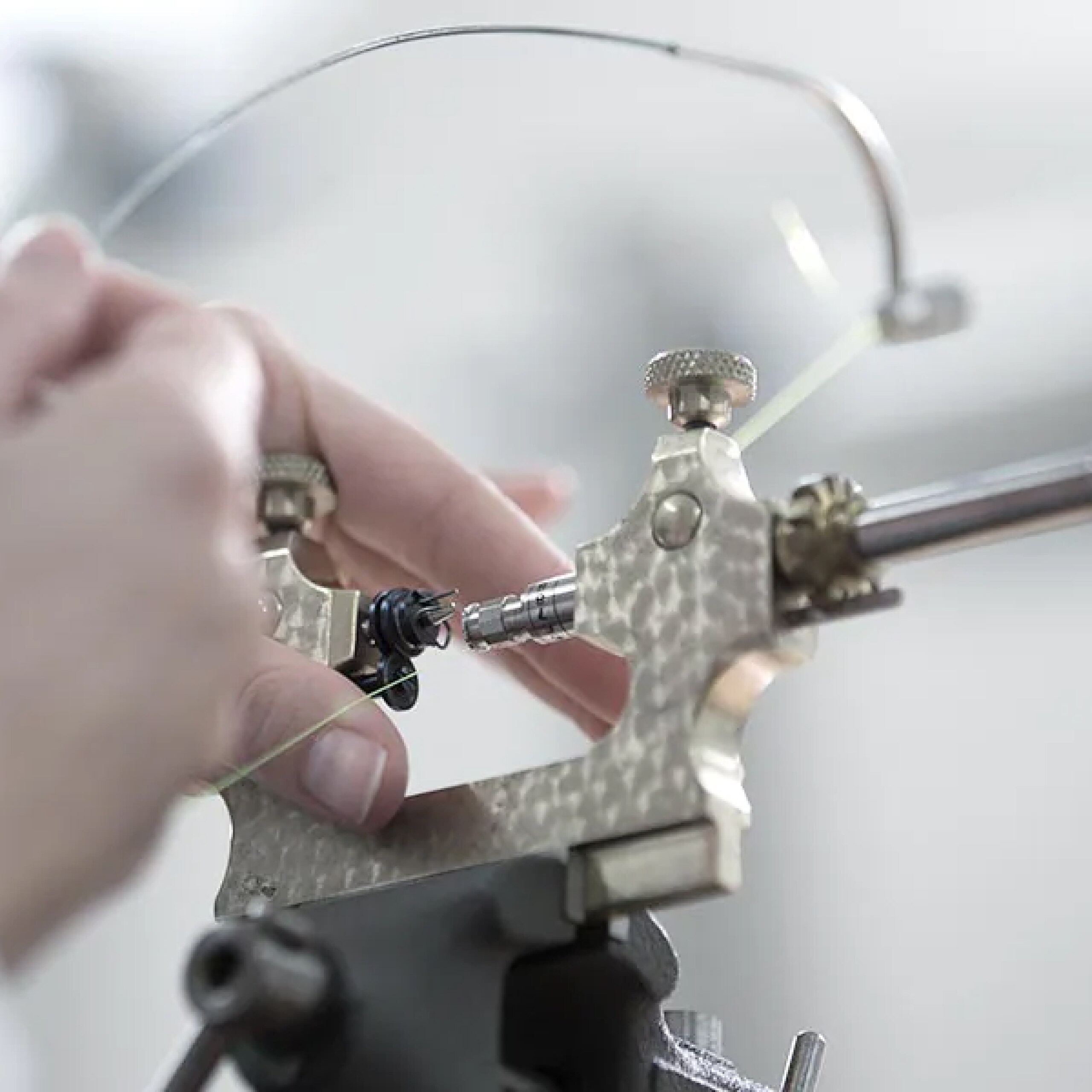

RESTORATION

The audio description stays synchronised with the video.

Transcript : Every ancient watch has a unique story and a priceless sentimental value for its owner. Your precious watch deserves the best possible service, so that its story lives on to the next generation.

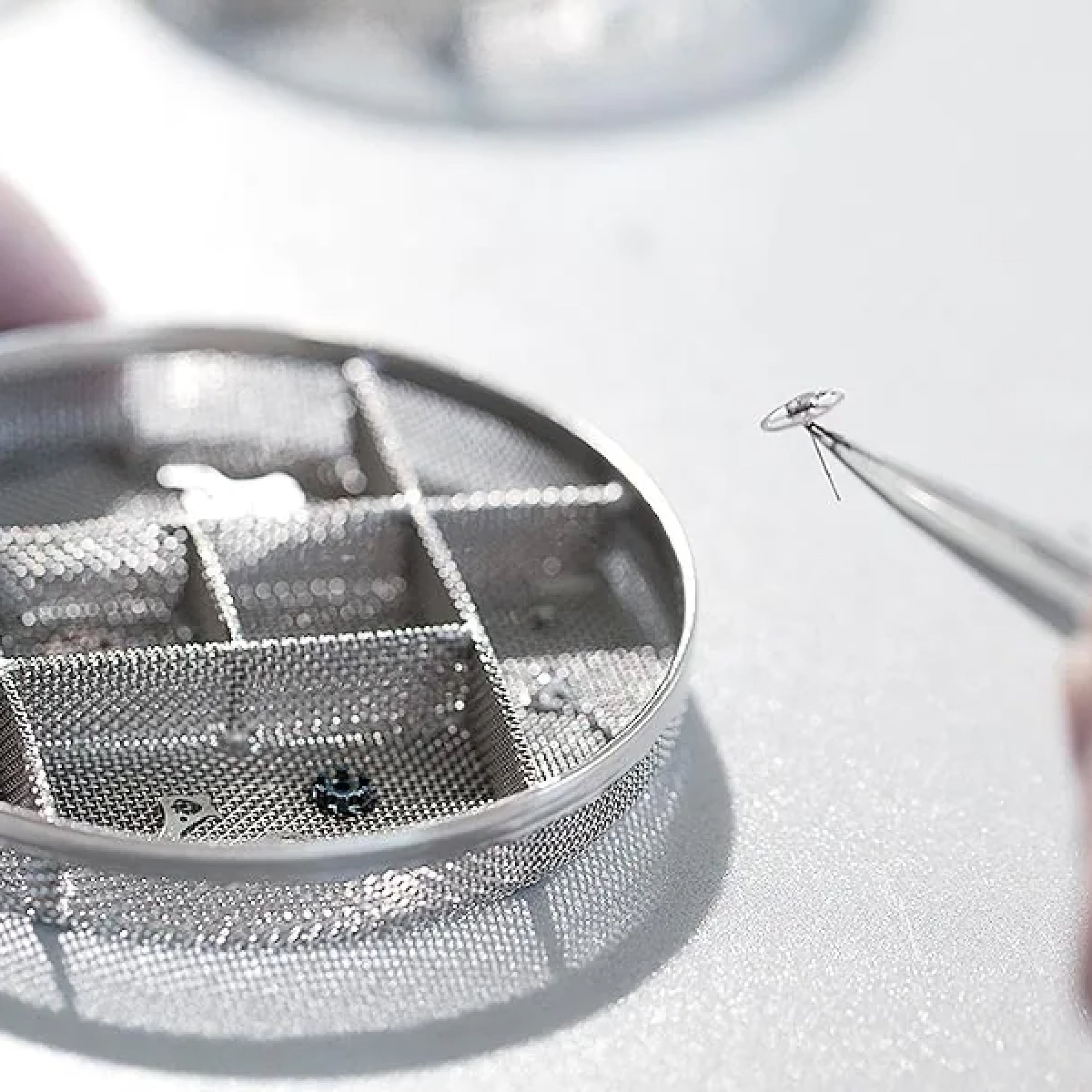

JEWELLERY

The audio description stays synchronised with the video.

Transcript : Your watch is more than just an accessory. It represents a precious heritage of memories and special moments. Over the years it may suffer the ravages of time, but you can be sure that our jewelers will restore it to its former glory.

POLISHING

The audio description stays synchronised with the video.

Transcript : Polishing can restore the original shine to a watch which has been worn for some time.